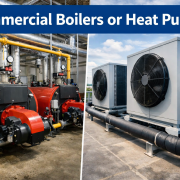

Replacing Commercial Gas Boilers with Large Heat Pumps – The Pros, the Cons, and the Reality

The Big Question Facing Commercial Estates

Across the UK, commercial building owners are under increasing pressure to move away from gas. Large commercial heat pumps are often presented as the obvious replacement — but the decision is rarely straightforward.

So what are the real pros and cons of replacing commercial gas boilers with large heat pumps?

This article cuts through the sales noise and looks at the practical, operational reality.

✅ The Pros of Large Commercial Heat Pumps

1. Significant Carbon Reduction

Heat pumps deliver immediate carbon savings, especially when paired with a low-carbon electricity supply. For organisations with net-zero targets, this is often the single biggest driver.

Why it matters:

Carbon reduction reporting, ESG targets, and future compliance are becoming board-level priorities.

2. High Seasonal Efficiency

Modern commercial heat pumps can achieve seasonal efficiencies far beyond traditional boilers when systems are designed correctly.

Key condition:

Low flow temperatures and well-matched emitters are essential.

3. Future-Proofing Against Regulation

Gas boilers face increasing regulatory pressure. Heat pumps reduce exposure to:

- Carbon taxes

- Fuel price volatility

- Future boiler restrictions

Long-term view:

This is about risk management as much as sustainability.

4. Integration with Hybrid Systems

Heat pumps don’t always need to replace boilers entirely. Hybrid systems allow:

- Heat pumps to cover base load

- Boilers to handle peak demand

- A phased decarbonisation strategy

⚠️ The Cons (and Challenges) of Replacing Gas Boilers

1. Electrical Infrastructure Limitations

Large heat pumps require substantial electrical capacity — something many older sites simply don’t have.

Reality:

Electrical upgrades can significantly impact project cost and programme.

2. Higher Capital Costs

Compared to like-for-like boiler replacement, heat pumps often require:

- New distribution strategies

- Buffer vessels

- Larger plant space

- Controls upgrades

Important point:

Lower running costs don’t always offset CAPEX in the short term.

3. Flow Temperature Constraints

Many existing commercial systems were designed for high flow temperatures.

Common issue:

Radiators, air heaters, or coils may not deliver enough heat at lower temperatures without modification.

4. Space and Planning Challenges

Large commercial heat pumps need:

- External space

- Noise considerations

- Structural support

- Planning coordination

This can be a major barrier in dense or city-centre locations.

5. Performance Depends on Design & Operation

Heat pumps are less forgiving than boilers:

- Poor commissioning = poor performance

- Incorrect controls = high running costs

- Lack of optimisation = disappointed clients

Technology isn’t the problem — execution often is.

The Real Answer: It’s Rarely “All or Nothing”

For many commercial buildings, the smartest approach is:

- Hybrid systems

- Phased replacement

- Strategic temperature reduction

- Controls and optimisation first

Boilers aren’t disappearing overnight — but doing nothing is no longer a safe long-term strategy.

How Cherwell Heating Approaches Heat Pump Transitions

We help commercial clients:

- Assess technical and electrical constraints

- Model energy, carbon, and lifecycle costs

- Design hybrid and phased solutions

- Deliver compliant, low-disruption installations

- Optimise performance long after handover

If you’re considering replacing boilers — or deciding not to — we’ll give you a straight answer